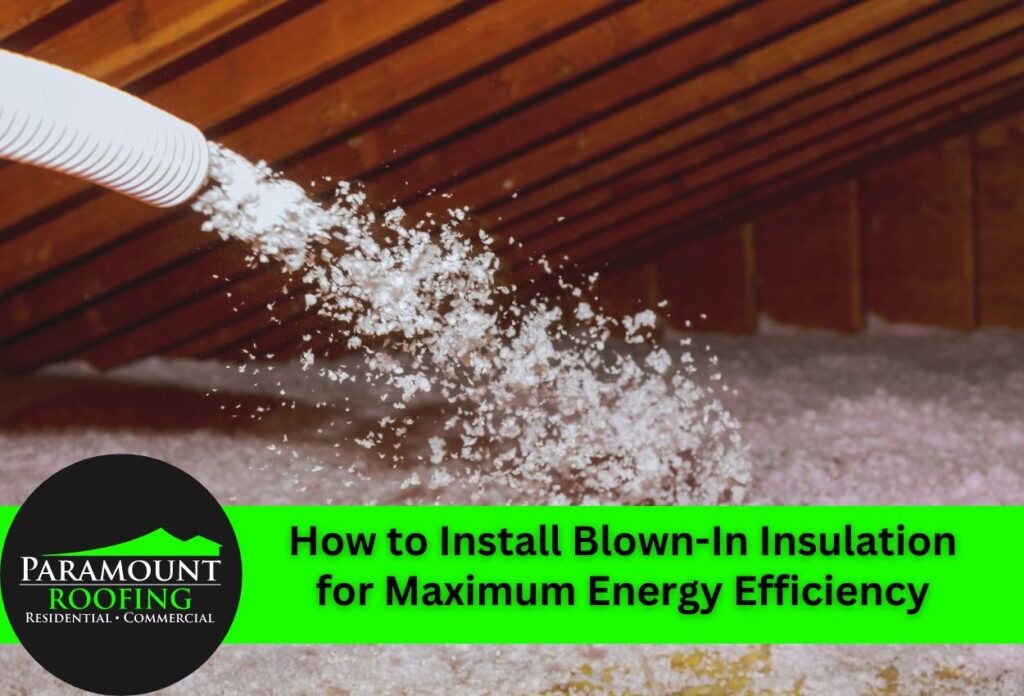

How to Install Blown-In Insulation for Maximum Energy Efficiency

Blown-in insulation offers superior energy efficiency compared to traditional batt insulation, especially when installed in attics and wall cavities. Blown-in insulation creates a seamless thermal barrier that eliminates gaps and air pockets commonly found with rolled or batted materials. This loose-fill insulation method adapts to irregular spaces and fills around obstacles like wiring and plumbing, creating complete coverage throughout the installation area.

The installation process requires specific equipment, including an insulation blowing machine, safety gear, and quality insulation materials. Cellulose and fiberglass are two options for blown-in materials, each with advantages for different applications. Blown-in cellulose insulation provides excellent fire resistance and sound dampening, while fiberglass offers moisture resistance and consistent thermal performance.

Understanding attic insulation installation techniques helps DIYers achieve optimal results and maximum energy savings. The process involves calculating square footage, determining depth requirements, and maintaining consistent distribution patterns across the entire surface area. Preparation includes sealing air leaks, installing appropriate barriers, and ensuring vents remain unobstructed. Professional-grade results depend on maintaining steady machine operation, consistent material flow, and achieving recommended R-values for the specific climate zone.

Tools and Materials You Need for Blown-In Insulation Installation

Successful attic insulation installation begins with assembling the equipment and materials. An insulation blowing machine rental is necessary for any project, with options ranging from portable units suitable for smaller residential projects to commercial-grade machines for extensive applications. These machines feature adjustable settings to control material density and flow rates for consistent distribution throughout the installation area.

Safety equipment is also needed for attic insulation projects. Protective gear includes dust masks or respirators, safety goggles, work gloves, and long-sleeved clothing to prevent skin irritation during installation. Additional preparation materials include measuring tapes for calculating coverage areas, marking chalk for establishing installation boundaries, and plastic sheeting to protect surrounding surfaces from material overspray.

The insulation material chosen impacts the effectiveness of the new installation. Cellulose offers superior fire resistance and sound absorption properties, making it ideal for residential applications. Fiberglass provides excellent moisture resistance and maintains consistent thermal performance across different climate conditions. Mineral wool delivers enhanced fire protection and acoustic benefits but requires specialized handling techniques. Each material type requires specific machine settings and installation approaches to achieve optimal R-values and coverage patterns throughout the targeted space.

Pre-Installation Safety and Workspace Preparation

Safety preparations are crucial for any successful blown-in insulation project. Adequate ventilation is essential when working with loose-fill insulation methods, as airborne particles can create respiratory hazards without proper air circulation. Installing temporary fans or opening multiple access points helps maintain air quality throughout the attic insulation installation. Electrical safety requires shutting off power to circuits running through the work area and using battery-powered lighting to illuminate the workspace effectively.

Personal protective equipment extends beyond basic dust masks to include full-face respirators when working with blown-in insulation materials. Heavy-duty work gloves protect hands from sharp objects and insulation fibers, while coveralls prevent skin contact and contamination of personal clothing. Safety glasses with side shields guard against airborne particles that standard eyewear cannot block during the insulation work.

Workspace preparation involves sealing air leaks around electrical outlets, plumbing penetrations, and recessed lighting, which prevents energy loss and ensures optimal insulation performance. Installing vapor barriers in appropriate climate zones controls moisture and prevents condensation issues within the building envelope. Clearing obstacles like stored items, old insulation debris, and construction materials creates unobstructed pathways for equipment operation and material distribution. Preparing the workspace before beginning the project allows for consistent coverage and eliminates potential safety hazards during the installation process.

Step-by-Step Blown-In Insulation Installation Process

The blown-in insulation process begins with machine setup and material preparation. Position the insulation blowing unit on level ground near the electrical source with adequate clearance for ventilation and material loading. Connect the delivery hose securely to the machine outlet, checking all fittings for tight seals to prevent material loss during operation. Load the hopper with the loose-fill insulation material according to manufacturer specifications, breaking apart any compressed bales to achieve consistent material flow through the system.

Establishing a clear hose route from the machine to the installation area requires strategic planning to minimize material waste and ensure smooth operation. Route the hose through the most direct path possible, avoiding sharp bends or kinks that could restrict airflow and material distribution. Secure the hose at regular intervals to prevent movement during operation, and ensure the delivery end remains easily maneuverable throughout the workspace.

Attic insulation installation begins at the furthest point from the access opening, working toward the exit point. Start the installation by using steady, overlapping passes to maintain consistent depth across all surfaces. Keep the hose end a few feet above the installation surface, moving in smooth arcs to distribute material evenly. Monitor depth markers regularly to achieve recommended R-values, adjusting machine settings as needed to maintain proper density and coverage throughout the space.

Achieving Proper Coverage Depth and Insulation Distribution

Maintaining correct insulation thickness throughout the blown-in insulation process requires consistent measurements and monitoring during installation. Depth gauges and measuring sticks help verify that the insulation is at the recommended R-values for specific climate zones. Insulation depths for residential properties vary depending on the material type and local energy codes. Regular measurements at multiple points across the attic space ensure uniform coverage and identify areas requiring additional material application.

Calculating R-values begins with understanding regional climate requirements and building code specifications. Northern climates typically need higher R-values, while lower values may be sufficient in moderate climates. The specific insulation material, whether fiberglass, cellulose, or mineral wool, determines the exact depth needed to achieve these thermal resistance values.

Navigating obstacles during attic insulation installation requires careful attention to detail. Working around electrical wiring, plumbing lines, and HVAC ductwork needs precise material placement to avoid creating thermal bridges or coverage gaps. Use targeted blowing techniques to fill spaces around joists and structural members, ensuring complete encapsulation without compressing the insulation material. Maintain clearances around recessed lighting fixtures and exhaust fans to prevent fire hazards while achieving comprehensive thermal coverage. Insulation blowing equipment allows for controlled material flow that accommodates these irregular spaces effectively.

Post-Installation Quality Check and Performance Optimization

A thorough inspection following the blown-in insulation process identifies any deficiencies requiring immediate attention. Begin the quality assessment by examining coverage depth across the entire installation area using measuring sticks at regular intervals. Areas around structural obstacles, corners, and edges often require additional attention to prevent thermal bridging and energy loss. Document depth measurements at multiple locations to verify consistent R-values throughout the attic space.

A visual inspection can reveal settling patterns and gaps that may have developed during the installation. Areas showing excessive compression or uneven distribution indicate improper machine settings or installation technique issues. Check for material displacement around ventilation baffles, electrical fixtures, and plumbing penetrations where airflow during installation may have created coverage inconsistencies. Identify and mark any sections requiring supplemental material application before completing the project.

Final steps in the project involve cleanup procedures and equipment maintenance. Remove all protective coverings, dispose of empty material bags according to local regulations, and vacuum any scattered insulation from surrounding surfaces. Clean the blowing machine components thoroughly before returning rental equipment, checking hoses and fittings for damage or wear. Create detailed installation documentation, including material types, coverage areas, achieved R-values, and project dates for warranty purposes and future reference during home energy assessments or renovations.

Maintenance and Long-Term Performance of Your Blown-In Insulation

Understanding the long-term performance characteristics of blown-in insulation helps homeowners maintain energy efficiency throughout the material’s lifespan. The blown-in insulation process creates effective thermal barriers, but these systems require periodic monitoring for continued performance. Normal settling occurs naturally over time as loose-fill insulation methods allow materials to compact slightly under their own weight and building movement. The amount of gradual settling depends on the specific material type and installation technique used.

Blown-in cellulose insulation generally has excellent long-term stability with minimal settling compared to alternatives. Regular performance monitoring involves checking insulation depth at multiple points across the attic space annually, particularly after severe weather or significant temperature fluctuations. Energy bills provide reliable indicators of insulation performance, with unexplained increases in heating or cooling costs often signaling thermal barrier degradation or coverage gaps requiring attention.

Several warning signs indicate when additional insulation becomes necessary to maintain your home’s thermal performance. Visible reduction in material depth around structural members, air leaks through light fixtures, or uneven surface coverage patterns suggest the need for supplemental material application. A professional assessment is valuable when attic insulation installation shows signs of moisture damage, pest intrusion, or contamination that compromises its effectiveness. Spot treatments using rental insulation blowing equipment allow targeted repairs without complete system replacement, making maintenance both practical and affordable for homeowners seeking sustained energy efficiency benefits.

Ensure Your Home’s Comfort with Paramount Roofing’s Expert Blown-In Insulation Services

If you’re looking to enhance the energy efficiency and comfort of your home, understanding how to install blown-in insulation is crucial. Paramount Roofing specializes in high-quality blown-in insulation services that cater specifically to the challenging climate in Detroit. Professional installation ensures that your home maintains a consistent temperature, reducing heating and cooling costs significantly.

Don’t let improper insulation techniques compromise your home’s energy efficiency. Contact Paramount Roofing today at (586) 690-0227 to schedule a consultation. Our expert team is equipped with the right tools and experience to install insulation correctly and efficiently, providing you with immediate comfort and long-term savings. Take the first step towards a more energy-efficient home by calling us now!

Free Estimate

Free Estimate

Request Service

Request Service Locations

Locations