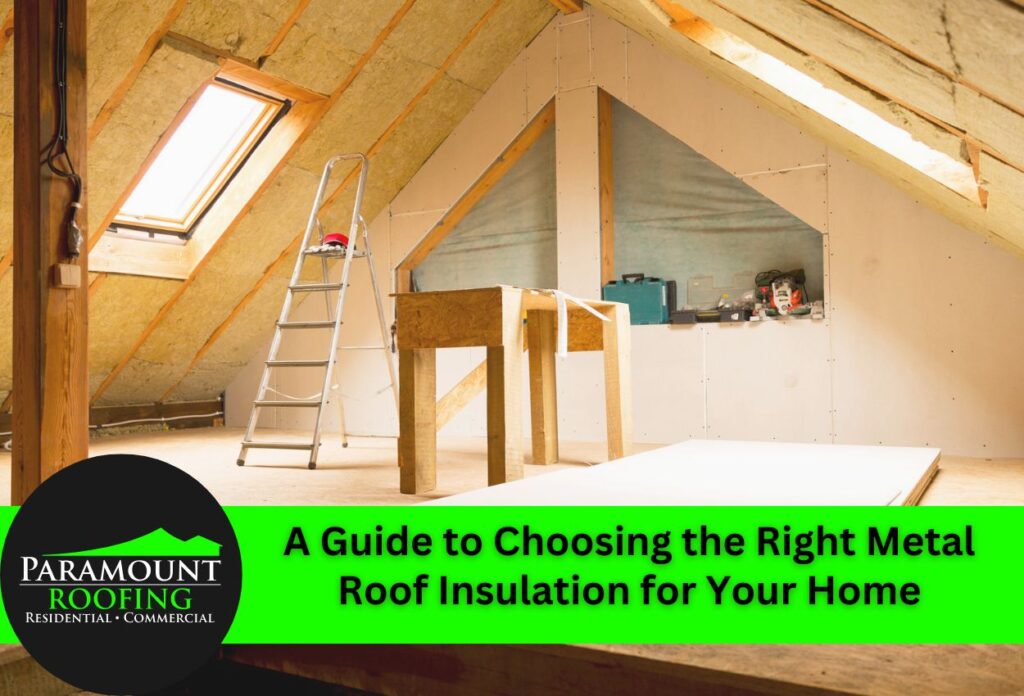

A Guide to Choosing the Right Metal Roof Insulation for Your Home

Metal roofs offer exceptional durability and longevity, but without proper insulation, they can create uncomfortable temperature swings and higher energy bills. The best metal roof insulation option depends on several factors, including climate conditions, budget considerations, and specific performance goals for your home.

Proper insulation serves as a critical barrier between your living space and the metal roofing material above. During summer, metal roofs absorb significant heat from direct sunlight, potentially turning attics into furnaces without adequate thermal protection. Winter conditions present the opposite challenge, as metal conducts cold temperatures that can lead to heat loss and ice dam formation.

Several types of insulation for a metal roof exist, each offering distinct advantages. Traditional batt insulation remains a popular choice for its affordability and ease of installation. Reflective insulation works by bouncing radiant heat away from the structure, while spray foam insulation creates an airtight seal that prevents thermal bridging.

Metal roof thermal performance improves dramatically when the right insulation system is selected and properly installed. Energy-efficient metal roof insulation not only reduces heating and cooling costs, but it also enhances indoor comfort by maintaining more consistent temperatures throughout the year. Understanding the characteristics of each insulation type helps homeowners make informed decisions that maximize their investment.

Understanding How Metal Roofs Handle Temperature Without Insulation

Metal roofing materials possess high thermal conductivity, meaning they transfer heat and cold much more efficiently than asphalt shingles or wood materials. This characteristic makes uninsulated metal roofs particularly susceptible to temperature fluctuations that directly impact indoor comfort levels.

During hot summer days, metal roofs can reach temperatures exceeding 150 degrees Fahrenheit, conducting this heat directly into attic spaces and living areas below. During winter, metal surfaces become extremely cold, creating pathways for indoor air to escape as it rises and cold outdoor air to get into the building as it sinks.

Homeowners with uninsulated metal roofs frequently experience several common problems that affect both comfort and energy efficiency. Condensation issues occur when warm, humid indoor air hits cold metal surfaces, leading to moisture buildup that can damage structural components and promote mold growth. Temperature fluctuations create noticeable hot and cold spots throughout the home, forcing HVAC systems to work harder and consume more energy.

Without proper thermal barriers, metal roof thermal performance remains poor, resulting in higher utility bills and inconsistent indoor temperatures. The type of insulation for a metal roof becomes important for addressing these thermal bridging issues. Energy-efficient metal roof insulation systems help break the direct thermal connection between exterior metal surfaces and interior spaces, creating more stable and comfortable living environments while reducing long-term energy costs.

Reflective Insulation Systems for Maximum Heat Protection

Reflective insulation for metal roofs operates by bouncing radiant heat away from the structure rather than absorbing it like traditional insulation materials. This technology utilizes aluminum foil facings or metalized surfaces that reflect up to 97% of radiant energy, making it an exceptionally effective type of insulation for a metal roof system.

The air gap between reflective barriers and metal roofing surfaces is the key to their superior performance. This space prevents conductive heat transfer while the reflective surface handles radiant heat, resulting in significantly improved metal roof thermal performance. During peak summer conditions, reflective systems can reduce attic temperatures by 30 degrees or more compared to uninsulated metal roofs.

Several reflective insulation products serve different performance requirements. Radiant barriers combine structural decking with integrated reflective surfaces, providing dual functionality during new construction projects. Bubble-wrap style reflective insulation offers flexibility for retrofit applications, featuring multiple air chambers between reflective layers for enhanced thermal resistance.

Reflective foil-faced batts combine traditional fibrous insulation with reflective surfaces, delivering both conductive and radiant heat protection. These hybrid products work particularly well as energy-efficient metal roof insulation.

Spray Foam Insulation for Complete Air Sealing

Spray foam insulation for metal roofs provides unmatched air sealing capabilities that eliminate thermal bridging and prevent energy waste through air leaks. This expanding insulation material fills every gap, crack, and irregular space between metal roofing components, creating a thermal barrier that traditional insulation cannot achieve.

The superior sealing properties make spray foam an excellent type of insulation for a metal roofing system where air infiltration poses significant energy efficiency challenges. Metal roof assemblies often contain numerous fasteners, joints, and connections that allow conditioned air to escape and outdoor air to enter. Spray foam expands to seal these problem areas completely, resulting in dramatically improved thermal performance.

Open-cell spray foam offers lower density and cost-effectiveness while providing excellent air sealing and sound-dampening properties. This option works best in moderate climates where moisture vapor permeability benefits indoor air quality. The softer texture allows for easier trimming and adjustment after installation.

Closed-cell spray foam delivers higher R-values per inch and superior moisture resistance, making it ideal for extreme weather conditions and areas prone to humidity problems. This denser material provides structural reinforcement while creating a vapor barrier. Closed-cell applications work particularly well as energy-efficient metal roof insulation in harsh climates where maximum thermal protection is essential. Both options eliminate air movement that reduces insulation effectiveness, ensuring consistent temperatures and lower energy consumption year-round.

Traditional Insulation Materials That Work Well with Metal Roofs

Fiberglass batts and rigid foam boards remain popular choices for metal roof insulation due to their proven effectiveness, affordability, and widespread availability. These traditional materials can achieve excellent metal roof thermal performance when properly selected and installed with appropriate techniques that address the unique challenges of metal roofing systems.

Fiberglass batt insulation works effectively as a type of insulation for a metal roof when installed with careful attention to air sealing and moisture control. The key to successful batt installation involves creating proper air barriers using house wrap or vapor barriers that prevent air movement through the insulation. Faced batts with vapor retarder backing help control moisture migration, while unfaced batts allow for separate vapor barrier installation that provides more flexibility in different climate conditions.

Rigid foam boards offer superior thermal resistance and structural stability that complement metal roofing installations. Polyisocyanurate foam boards provide high R-values per inch and work particularly well in continuous insulation applications. Extruded polystyrene boards resist moisture absorption and maintain consistent thermal performance over time, making them reliable for long-term energy-efficient metal roof insulation systems.

Factors That Determine the Best Choice for Your Specific Situation

Selecting the best metal roof insulation option requires a look at multiple factors that influence both installation success and long-term performance. Your home’s unique characteristics, local weather patterns, and existing structural elements all play important roles in determining which type of insulation for a metal roof will deliver the best results.

The design of the home significantly impacts insulation selection decisions. Cathedral ceilings with limited space between the roofing and the interior of the home favor high-performance options like spray foam insulation for metal roofs or reflective insulation for metal roofs that maximize thermal protection within confined areas. Traditional attic spaces with adequate clearance accommodate various insulation types, providing more flexibility in material selection and installation approaches.

Local climate conditions directly affect which insulation characteristics matter most for your specific situation. Hot, sunny climates benefit from reflective insulation systems that handle intense radiant heat loads effectively. Cold winter regions require higher R-value materials that prevent heat loss and minimize ice dam formation. High-humidity areas need vapor-permeable or moisture-resistant options that prevent condensation problems.

The existing roof structure influences installation complexity and material compatibility. Older homes may require structural reinforcement before adding heavier insulation systems. New construction projects allow for integrated approaches that combine multiple insulation types for maximum energy-efficient metal roof insulation performance.

Working with Professional Contractors for Proper Installation

Professional installation plays a critical role in achieving optimal metal roof thermal performance and preventing expensive moisture or air sealing problems that can compromise insulation effectiveness. Expert contractors understand the complex interactions between metal roofing systems and various insulation materials, ensuring proper installation techniques that maximize energy-efficient metal roof insulation performance while avoiding common pitfalls that affect long-term durability.

Experienced contractors possess specialized knowledge about vapor barrier placement, ventilation requirements, and thermal bridging prevention that directly impacts the success of any type of insulation for a metal roof project. Improper installation can lead to condensation problems, air leaks, and reduced thermal protection that negates the benefits of quality insulation materials. Professional installation ensures the materials are handled correctly, appropriate sealing techniques, and compliance with building codes that protect your investment.

When evaluating potential contractors, ask specific questions about their experience with metal roof insulation projects and request references from recent installations. Inquire about their preferred methods for installing reflective insulation for metal roofs or spray foam insulation for metal roofs, depending on your selected approach. Qualified professionals should explain ventilation strategies, moisture control measures, and warranty coverage for their installation work.

During the installation process, expect contractors to conduct thorough site preparation, protect existing surfaces, and follow manufacturer specifications for your chosen insulation system. Quality contractors provide detailed documentation of installation procedures and performance specifications that support warranty claims and future maintenance requirements. Professional teams coordinate material delivery, weather considerations, and safety protocols while maintaining clean work areas and proper disposal of materials.

Choose Paramount Roofing for Your Metal Roof Insulation Needs

Ensuring your home is comfortable and energy-efficient year-round starts with choosing the right insulation for your metal roof. At Paramount Roofing, we specialize in providing top-notch insulation solutions tailored to your specific needs.

Whether you’re considering the superior air sealing properties of spray foam insulation or the reflective benefits of a radiant barrier, our expert team is here to help. Don’t let your energy bills soar or suffer from indoor temperature fluctuations.

Call us today at (586) 690-0227 to discuss the best metal roof insulation option for your home. Let Paramount Roofing help you achieve optimal thermal performance and energy savings!

Free Estimate

Free Estimate

Request Service

Request Service Locations

Locations